What Makes an Optical Communication Test Platform Truly Intelligent?

2025-07-11

Modern optical communication systems are becoming increasingly complex. Components such as transceivers, amplifiers, WDM modules, and optical switches must undergo rigorous testing across multiple wavelengths, power levels, and signal conditions. Manual setups are error-prone, time-consuming, and inconsistent—making them unsuitable for high-volume manufacturing or advanced R&D environments.

By integrating intelligent, programmable optical modules into a unified test platform, manufacturers can streamline test workflows, automate data acquisition, and perform multi-channel, multi-parameter analysis with minimal human intervention.

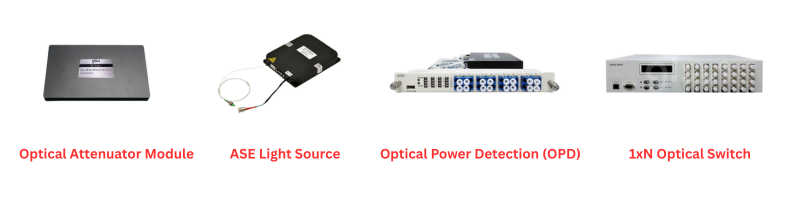

Key Components of an Intelligent Optical Test Platform

1. ASE Light Source: Stable, Broadband Optical Signal Generation

An Amplified Spontaneous Emission (ASE) Light Source provides the stable and broad-spectrum optical signal necessary for testing a wide range of passive and active optical components. It is commonly used in scenarios such as insertion loss testing, component spectral characterization, and WDM system simulation.

Core Features:

>> Broadband Output (C+L Band): Suitable for testing across multiple channels or wavelength bands.

>> High Stability: Output power fluctuations are minimized to ensure consistent results.

>> Compact Design: Suitable for integration in modular platforms or benchtop setups.

The reliability of the ASE light source directly impacts the repeatability and precision of optical measurements. In high-throughput environments, stable broadband emission simplifies wavelength-dependent characterization, accelerating test cycles.

2. Optical Attenuator: Precision Power Control for Accurate Measurements

The Optical Attenuator plays a critical role in simulating real-world network conditions by adjusting the optical signal strength before it enters the device under test (DUT). This control is essential for validating device performance under varying power levels.

Core Features:

>> Variable Optical Attenuation: Ranges from low to high dB levels with fine-tuned resolution.

>> Low Insertion Loss and High Return Loss: Maintains signal integrity.

>> Programmable and Remote-Controlled: Easily integrated into automated test systems.

Using a precision optical attenuator ensures that optical receivers are tested for sensitivity, overload tolerance, and power-dependent behaviors—key parameters for qualifying network performance.

3. 1xN Optical Switch: Multi-Channel Routing for Automated Test Sequences

A 1xN Optical Switch allows a single input signal to be routed to one of multiple output ports (or vice versa), making it ideal for parallel testing of multiple devices or sequential testing across different signal paths.

Core Features:

>> Scalable Port Configurations (1x4, 1x8, 1x16, etc.): Supports complex test matrices.

>> Fast Switching Time: Enables high-speed testing and quick reconfiguration.

>> Low Crosstalk and Insertion Loss: Preserves signal fidelity.

In automated testing scenarios, 1xN optical switches eliminate the need for manual reconnections. They enable round-robin testing across many ports, accelerating throughput and reducing setup errors.

4. Optical Power Detector (OPD): Real-Time Monitoring for Power Accuracy

An Optical Power Detector (also known as an Optical Power Meter or Monitor) provides real-time feedback on signal levels, enabling the platform to ensure consistent power delivery and validate test accuracy.

Core Features:

>> High Sensitivity and Accuracy: Detects low and high power levels with minimal error.

>> Multi-Channel Monitoring: Supports simultaneous measurements on different paths.

>> Data Logging and Integration: Compatible with test management software.

With real-time optical power detection, engineers can verify whether the signal meets predefined criteria and dynamically adjust attenuators or light sources as needed. This closed-loop capability supports high-yield production testing and reliable quality control.

System Integration: Building the Intelligent Test Platform

When these four components—ASE Light Source, Optical Attenuator, 1xN Optical Switch, and Optical Power Detector—are integrated into a cohesive testing platform, the result is a powerful system capable of:

>> Automated Test Workflows: Reducing human error and increasing test consistency.

>> Multi-Channel Operation: Testing several DUTs in parallel or in sequence.

>> Dynamic Power Control: Real-time adjustment of signal strength for various test scenarios.

>> Data Logging and Traceability: Ensuring all measurements are recorded and traceable for audits or certification.

Advanced test management software can coordinate the behavior of each component, controlling switch positions, setting attenuation levels, triggering power readings, and logging results—all via a user-friendly interface or script-based automation.

This level of integration enables manufacturers to scale up production testing, reduce turnaround time, and maintain stringent quality standards across all products.

Applications in Modern Optical Manufacturing

Smart optical communication test platforms are vital across various stages of product development and manufacturing, including:

>> Transceiver Module Testing: BER, insertion loss, return loss, and sensitivity validation.

>> WDM System Characterization: Channel power equalization, spectral shaping.

>> Component Reliability Testing: Burn-in and environmental stress testing under controlled power conditions.

>> Factory Automation: Integration into robotic arms and conveyor-based inspection systems.

As the industry moves toward higher speeds (400G/800G/1.6T), greater integration (SiPh, Co-Packaged Optics), and tighter tolerances, the role of intelligent test platforms becomes even more critical.

Integrating all these optical modules into a unified system dramatically improves testing efficiency and data accuracy—fueling the advancement of smart optical manufacturing. As the industry embraces AI-driven production and zero-defect delivery, intelligent optical communication test platforms are no longer optional—they are essential.